Air Movement & General Ventilation Industrial Centrifugal Fans

Purpose: Efficiently move large volumes of clean air for HVAC and general ventilation.

Applications: Office buildings, commercial spaces, general manufacturing, HVAC systems.

Includes: Forward Curved Fans, Utility Fans, Plug Fans.

These fans are designed to move high volumes of clean air efficiently and quietly, making them ideal for HVAC systems, manufacturing plants, and commercial spaces. Whether it's general ventilation or consistent airflow across a facility, this category covers a wide range of standard air movement needs.

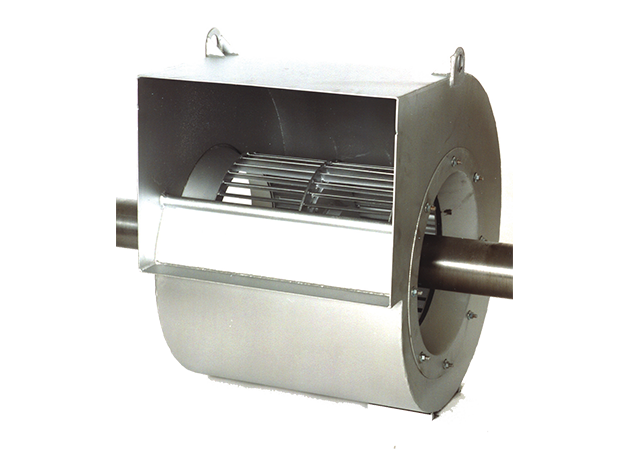

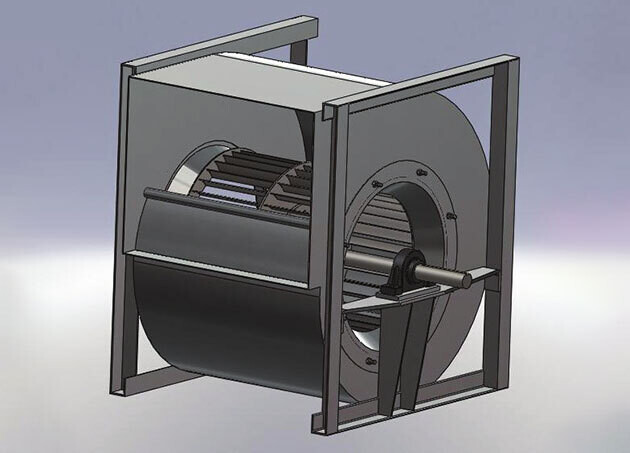

Forward-curved fans (sometimes called squirrel-cage fans) are compact, low-noise, and well-suited for systems that require high airflow at low static pressure.

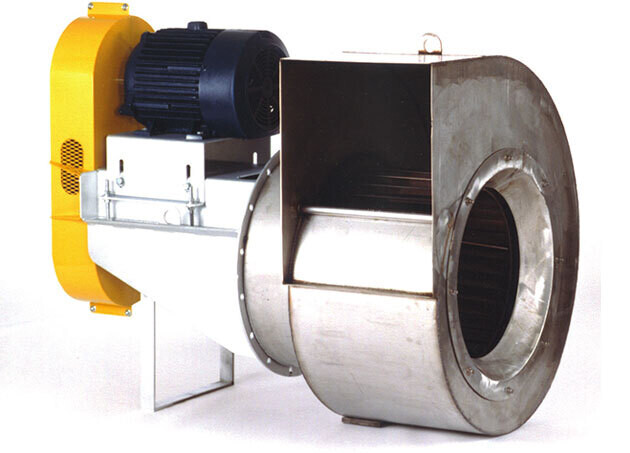

Utility fans are housed centrifugal units used in everything from basic fume exhaust to kitchen ventilation and commercial air handling.

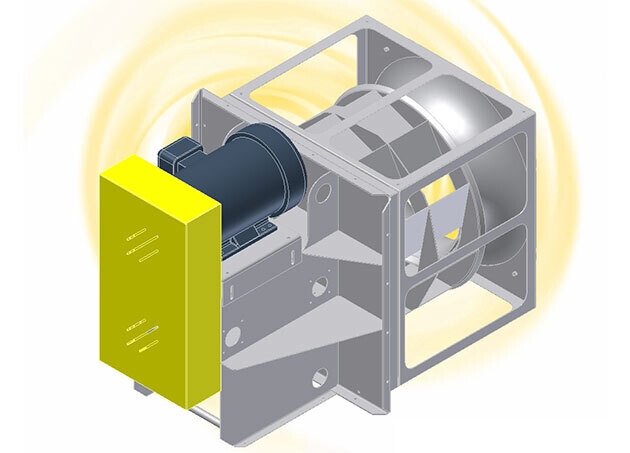

Plug fans, meanwhile, mount directly into enclosures like Air handling units or process units. They're typically direct-drive and compatible with variable frequency drives, making them efficient and space-saving.

Specialty & Custom Applications

Not every airflow challenge fits neatly into a category. We regularly help engineers and end users specify custom fan solutions for test stands, prototypes, specialized machinery, and non-standard environments. Let us know what you’re working on—we’re here to help.

Oil and Gas

Industrial fans support extraction, refining, and handling of hydrocarbons by ventilating hazardous areas and managing vapor streams. Corrosion-resistant and spark-resistant construction is often critical.

Dust Collection & Filtration

Industrial fans power dust collection systems such as baghouses, cartridge collectors, and cyclones by delivering high-volume airflow and pressure. These fans remove hazardous or valuable particulates, maintain workplace air quality, and support compliance with safety and emissions standards.

Marine and Offshore Applications

Industrial fans are used aboard ships, barges, and offshore rigs to ventilate engine rooms, crew spaces, and cargo holds. Salt air resistance and explosion protection are often required for durability and safety.