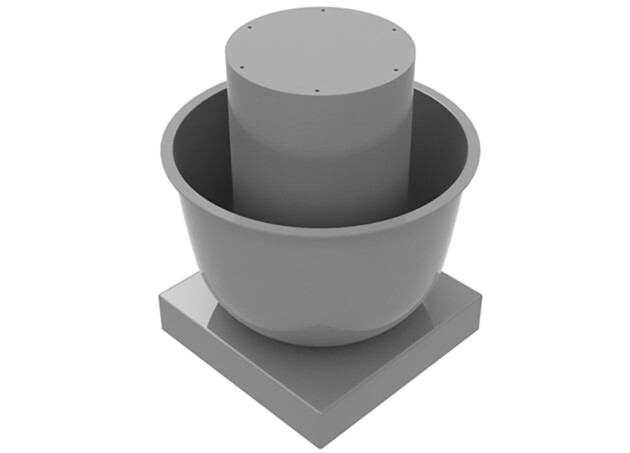

Corrosion-Resistant Fans | Chemical Duty Fans

Purpose: Handle aggressive chemicals, corrosive fumes, or moist environments.

Applications: Wastewater treatment, chemical processing, food production.

Includes: Fiberglass Reinforced Plastic (FRP) Fans, Stainless Steel Fans, Epoxy-Coated Blowers.

If your air system deals with corrosive fumes, harsh chemicals, or high humidity, you need fans that are built to resist those elements. Standard steel or aluminum just won’t hold up over time in these conditions.

FRP (fiberglass-reinforced plastic) fans are highly resistant to acids, alkalis, and solvents — commonly used in chemical plants, wastewater facilities, and marine settings.

Stainless steel fans are a good fit for less aggressive environments, offering corrosion resistance along with easy cleaning, which is especially important in food and pharmaceutical applications.

Epoxy-coated fans offer an economical solution for moderately corrosive conditions, such as paint booths or exhaust systems exposed to moisture or mild chemicals.

These fans are built for long service life in environments where corrosion would quickly destroy conventional models.