Corrosion-Resistant & Specialty Industrial Axial Fans

Purpose: Operate in harsh, corrosive, or specialized environments with unique airflow requirements.

Applications: Chemical plants, wastewater treatment, high-heat industrial applications, hazardous or explosive environments.

Includes: Fiberglass Reinforced Plastic (FRP) Axial Fans, High-Temperature Axial Fans, Explosion-Proof Axial Fans.

Specialty axial fans are essential for industrial operations where standard ventilation equipment can’t meet the demands of corrosive chemicals, high heat, or explosive atmospheres. These fans are engineered not only for performance but also for safety, longevity, and minimal maintenance in harsh conditions.

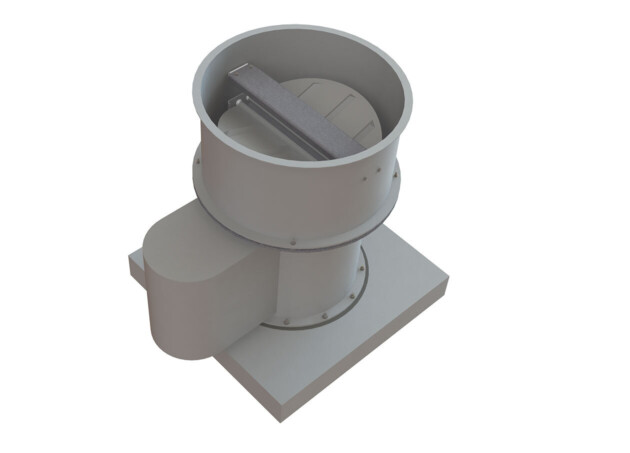

Corrosion-Resistant FRP Axial Fans

Axial fans made from fiber-reinforced plastic (FRP) are designed to withstand corrosive environments that would rapidly deteriorate metal fans. FRP offers excellent resistance to a wide range of chemicals, vapors, and moisture, making these fans suitable for use in chemical processing facilities, laboratories, water and wastewater treatment plants, pharmaceutical and food production, marine environments, mining, and electric vehicle battery manufacturing. Their lightweight, non-metallic construction reduces load stress and installation complexity

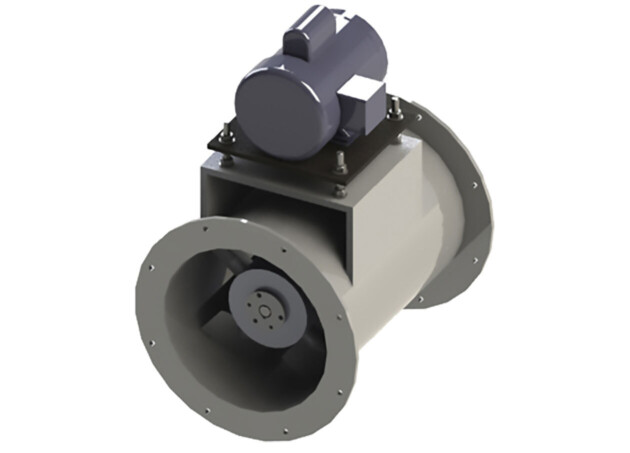

High-Temperature Axial Fans

Built for extreme heat, high-temperature axial fans are commonly used in applications such as oven and furnace exhaust, boiler venting, fire and smoke control, and power plant ventilation. These fans feature materials that operate reliably under fluctuating temperatures. Components include high-temperature bearings and lubricants, and heat-resistant construction materials to maintain performance and safety when exposed to elevated air or gas temperatures.

Hazardous Location Axial Fans

While the term “explosion-proof fan” is widely used, it's important to clarify that the fan itself is not explosion-proof—rather, it uses an explosion-proof motor (certified for hazardous environments) in combination with AMCA-rated spark-resistant construction. These axial fans are suitable for use in environments where flammable gases, vapors, dusts, or fibers are present, including petrochemical plants, grain storage, paint spray booths, ammunition depots, and fuel handling areas.

To reduce ignition risk, spark-resistant fans use non-ferrous materials—such as aluminum or bronze—for critical rotating components. Explosion-proof motors are rated for Class I or II, Division I or II hazardous locations per NEC or CSA standards.

Together, these specialty axial fans provide essential ventilation solutions across a wide range of industries. Whether the priority is corrosion resistance, high-temperature endurance, or safe operation in hazardous locations, proper fan selection ensures both operational efficiency and compliance with safety standards.