Heavy-Duty & Industrial Process Axial Fans

Purpose: Handle tough, continuous industrial applications where durability and reliability are critical.

Applications: Power plants, heavy manufacturing, mining ventilation, drying and cooling processes, high-static pressure environments.

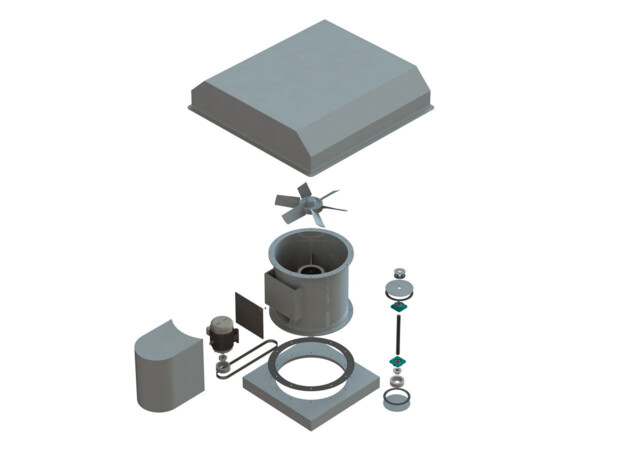

Includes: Belt-Drive Axial Fans and Direct-Drive Axial Fans.

When it comes to heavy-duty ventilation and industrial process air movement, axial blowers are a go-to solution for delivering reliable, high-volume airflow. This group of industrial axial fans is essential for applications that require high airflow volumes at low to moderate pressure. Whether you're cooling a warehouse, ventilating a production area, or exhausting air through ductwork, the right fan type can make a big difference in performance, efficiency, and longevity. The two most common drive configurations—belt-driven and direct-drive—each offer distinct advantages depending on the environment and airflow demands.

Belt-Driven Axial Fans position the motor outside the airstream, protecting it from heat, humidity, fumes, and other contaminants. This makes them ideal for high-temperature or corrosive environments. Airflow and static pressure can be adjusted by changing belts or sheaves, offering more flexibility when system requirements vary. Their rugged construction also makes them well-suited for continuous, demanding use in industrial settings.

Direct-Drive Axial Fans, on the other hand, have the impeller mounted directly to the motor shaft. This compact design offers several key benefits: higher energy efficiency, lower maintenance, and quieter operation. With fewer moving parts and no belts to replace, these fans are reliable, easier to install, and better suited for tight spaces or clean-air applications where simplicity and efficiency are priorities.

Ultimately, choosing between a belt-driven or direct-drive fan depends on factors like temperature exposure, space limitations, airflow adjustability, and maintenance expectations. Both offer powerful performance in the right setting.